Column Packing

Column Packing Ltd was established in 2018 having the capacity to manufacture random column packing namely Dixon Rings and Lessing rings by conventional manufacture.

The company had identified that there was opportunities using Additive Manufacturing techniques to produce column packing both in a random format and also in structured format. I

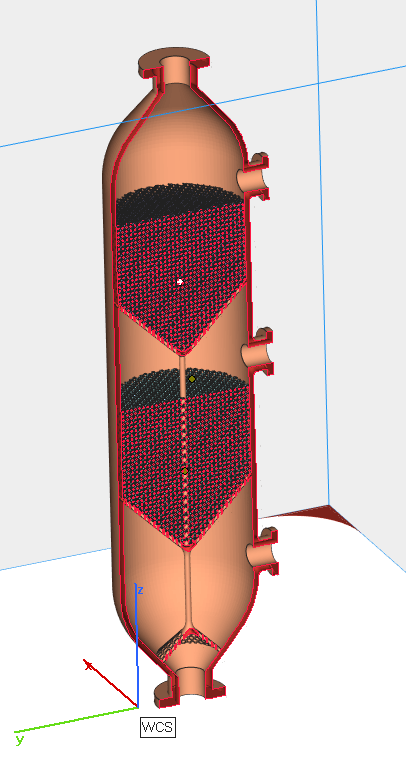

It was also identified that a single piece construction could be manufactured using additive manufacturing techniques that enabled a vessel to be built ,filled as required by the equivalent of column packing.

Commonly referred to as Design for Additive Manufacturing DfAM the construction methods utilised by additive manufacture give new opportunities for product development.

This includes the opportunities to produce column packing in materials that cannot be either manufactured or affordable utilising conventional material availability.

What is Column Packing?In chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packing can be randomly filled with small objects like Dixon Rings or else it can be a specifically designed structured packing. Packed beds may also contain catalyst particles or adsorbents such as zeolite pellets, granular activated carbon, etc.

Dixon rings manufacture

Dixon rings are currently manufactured using woven wire mesh. The most common material that is used is Stainless Steel 316 but they can also be manufactured in materials that can be woven is fine as 100 x 100mesh. These materials include phosphor bronze, brass, Inconel, Hastelloy, gold, silver and titanium.

The most common size for a Dixon ring is a 1/8 inch (3.3 mm) and then ¼ inch after that half inch and then 15 mm.

They can be manufactured to customer requirements

Lessing rings

Lessing rings are currently available as a 12.7 mm diameter 12.7 mm tall product these can be produced in any sheet material that is available At 0 .7 mm thick. To manufacture different sizes to customers requirements is a relatively inexpensive setup charge in that the manufacture of the forming equipment is comparatively cheap. Stainless steel is the most common material used for the manufacture of Lessing rings but again it is down to customers specific requirements

Additive Manufacturing (Metal 3D printing)

We have staff that have many years experience in additive manufacture. Most of the items that are designed and manufactured by ourselves are to customers specific requirements and as such we are tied to confidentiality agreements meaning we cannot reveal a lot of what we do.

Currently the additive manufacturing capacity that we offer as standard is a build platform of 200 mm x 200 mm x 200 mm in stainless steel 316 along with a machine with a build platform of 100 mm x 100 mm x 100 mm currently working with stainless steel 316 and Inconel. We have partners who produce in aluminium and titanium, all capable of offering short delivery times